|

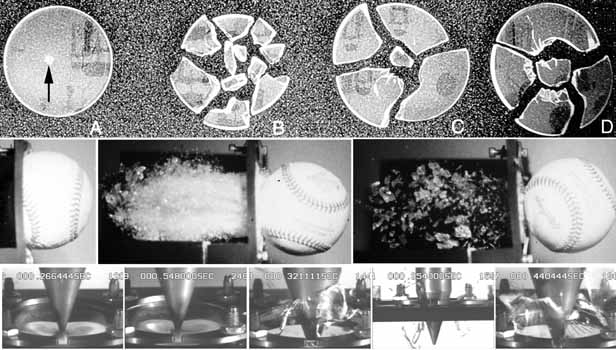

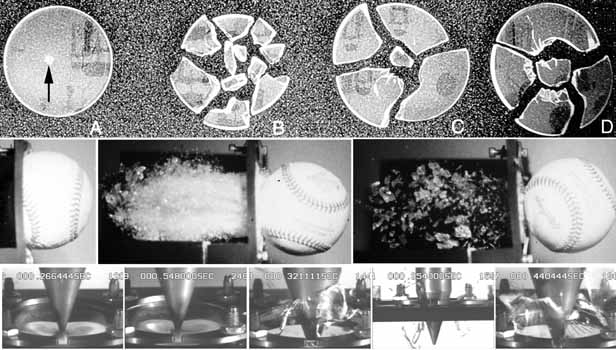

| Fig. 4 Impact resistance of eyewear lenses. Top row. BB impacts on (A) polycarbonate, (B) glass, (C) allyl resin plastic [CR–39], (D) high-index (1.6) plastic lenses. Center row. Baseball impact on industrial safety lenses (left) polycarbonate at 169 ft/s [note flattening of baseball], (center) glass, chemically tempered at 142 ft/s, (right) allyl resin (CR–39) plastic at 137 ft/s Bottom row. 500-g high-mass Z87 test object from left to right onto Trivex, polycarbonate, CR–39, high-index (1.6), and Spectralite lenses. All lenses, 2 mm thick plano. Mass dropped from 75 inches (9.34 J) onto Trivex and polycarbonate which did not shatter, and from 50 inches (6.23 J) on the other lenses that shattered.(Bottom row courtesy of Nancy Yamasaki) at velocities expected in typical sports, glass, allyl resin, and high index plastic lenses shatter, while polycarbonate (and also Trivex) remain intact. |